Printed circuit boards (PCBs) are now an integral part of everyday life across a variety of different industries — from medical and automotive to telecommunications and consumer electronics.

But how did we get to this point?

Like many other great inventions, the PCB that we know today was built on a foundation of advancements throughout history — going back over 130 years to the Progressive Era! During this time, we saw the first PCB emerge in 1903 when German inventor Albert Hanson filed a patent for a device described as a flat, foil conductor on an insulating board with multiple layers. Sound familiar?

A few decades later, during the Second World War, we then saw the first use of a PCB as we know it today. Used for high-velocity artillery shells, the proximity fuse was developed by the British to combat the Nazis before being perfected later in the US. Throughout this time, Paul Eisler also filed a patent for copper foil on a non-conductive base of glass — similar to the concept we still use today for manufacturing PCBs.

Growing in design and technology

Over time, PCBs have evolved as a tool for optimising the manufacture of electronics and the rate at which the design and technology have progressed in recent years is impressive.

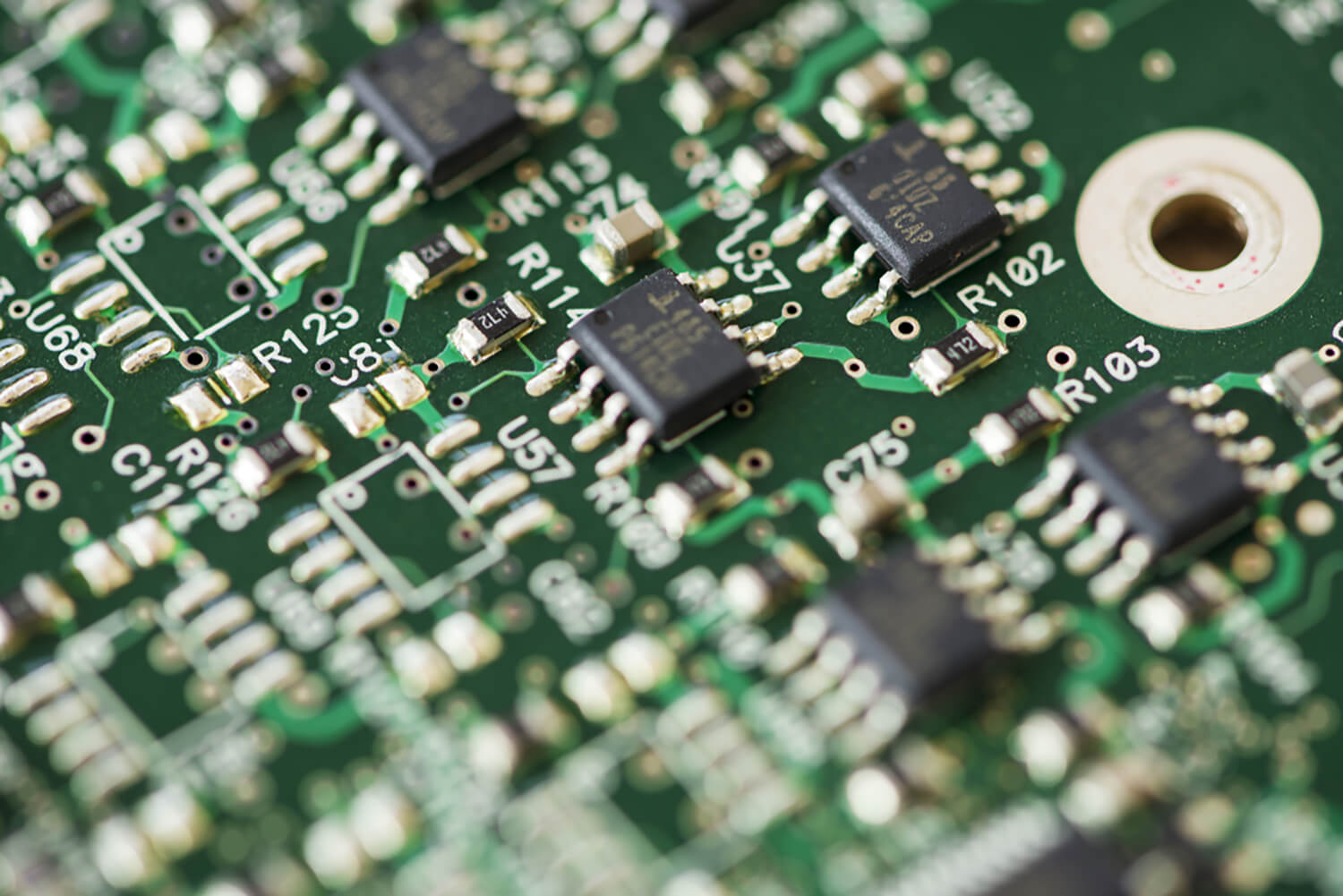

With these advances, we have seen noticeable trends in PCB manufacturing. Where once they were assembled easily by hand, now the microscopic components of PCBs require the increased precision and efficiency of machinery. This allows manufacturers to pack more functionality and complexity into smaller boards.

All of these developments are being driven primarily by our expectations. We’re demanding faster, cheaper and more powerful devices — often in smaller packages. And the only way to achieve this is by miniaturising the manufacturing process and making it more efficient.

Take video games, for example. Back in the 80s, kids would have been playing Pacman on gigantic arcade machines. Now, we’re seeing the likes of virtual reality goggles becoming, well, reality. This progress is incredible, and it’s largely thanks to PCBs.

Day-to-day uses

Today, the use of PCBs in electronics is widespread. They can be single-sided, double-sided or multilayer. They can be rigid, flexible or contain both rigid and flexible parts.

Most people use them every day without even realising it, and they play a critical part in the electronics used by a broad range of industries.

We take a look at some of the most common uses for PCBs…

Consumer electronics:

- Communications devices such as smartphones, tablets, smartwatches and radios

- Computers for both personal and business use

- Home appliances including refrigerators, microwaves and coffee makers

- Entertainment systems such as televisions, stereos and video game consoles

- Homeowners can light their property more efficiently using PCB-powered LED lighting such as smart bulbs

Medical devices:

- Imaging systems such as CT, CAT and ultrasonic scanners

- Heart rate, blood pressure and blood glucose monitors which depend on electronic components to obtain accurate readings

- Infusion pumps, such as insulin and patient-controlled analgesia pumps, use PCBs to reliably and accurately deliver precise amounts of fluid to the patient

- LEDs provide bright light and give off little heat, making them ideal for medical applications — especially those related to surgery and emergency medicine

- Pacemakers and other internal devices must use small PCBs which adhere to strict sanitation standards

Automotive:

- In-car entertainment and navigation systems

- Many systems that control the basic functions of the car, such as engine management systems and fuel regulators

- Dashboard indicators, headlights and brake lights

- Sensors which improve safety and help drivers to park more accurately

Safety and security equipment:

- Both indoor and outdoor security cameras, as well as the equipment used to monitor the footage

- Smoke and carbon dioxide detectors

- Modern electronic door locks

- The motion sensors in devices such as burglar alarms rely on PCBs to detect movement

Telecommunications:

- Cell towers require PCBs that can withstand outdoor environments to receive and transmit signals from cell phones reliably

- Most of the communication equipment you find in an office including modems, routers and phone systems

Many other sectors — including aerospace, military and defence, maritime and industrial —also use PCBs every day across several essential applications.

To discover what you could do with PCBs, contact us today to learn more about our PCB assembly services!