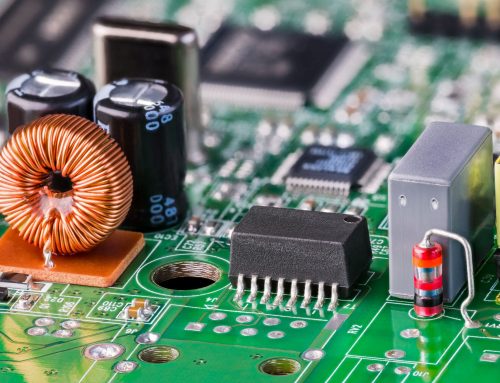

Manufacturing is one of the major drivers of our economy and to thrive in competitive markets, implementing the best electronics manufacturing processes is essential.

How can electronics manufacturers guarantee quality?

The electronics manufacturing services industry relies upon sourcing components from all over the world. With that, comes a perception that parts sourced from overseas suppliers carry a certain amount of ‘risk’. And rightly so. There are thousands of potential suppliers worldwide all making strong assertions of quality and sustainability. The Asian market, for example, is a complex and somewhat confusing sector to decipher when it comes to identifying good manufacturing partners.

How to ensure reputable suppliers in electronics manufacturing

We believe quality of supplier and product must be first place for an electronics manufacturing service company like ours. Because we often innovate new designs for customers, known as new product introduction, and dealing with large batch orders – quality is paramount.

We’ve decided to demonstrate supply chain excellence for two reasons. To put our customers at ease about the quality of the final product and guarantee the high standards they expect and demand. We apply these quality assurance ideas in our everyday practice:

- Our staff conduct supplier factory inspections at home and abroad to oversee quality – prior to goods being released for dispatch,

- sustainable manufacturing practices must be evident and

- all parts of the supply chain adhere to ISO standards.

Great quality delivers business growth

In a survey by domestic appliances manufacturer Miele almost four fifths (78%) of British manufacturers believe quality is the key to delivering business growth. So important is quality, 38% said it ranks higher on their list of concerns than financial performance. The research also found achieving quality in the supply chain is the second greatest challenge.

With literally tens of thousands of companies offering similar services and products, our dedicated EC Supply Chain Solutions team investigates every one of our suppliers across the manufacturing spectrum. Whether inspecting, visiting, auditing or selecting new suppliers, it’s our priority to build strong relationships which match up to our high standards and suit our markets, both worldwide and in Europe.

What sustainability issues should electronics manufacturers have to think about?

Nearly half of organisations in the Miele survey rated issues with outsourcing abroad their greatest challenge. Of primary concern is ethical sourcing and sustainability. Locating raw materials that meet international standards for provenance means quality procedures need repeated overhauls.

All our electronics manufacturing services are committed to internationally recognised standards, including our Asian suppliers. We only work with Asian suppliers who work to IPC Standards, including Class 3. Additionally, we’re signed up to the ISO/TS 16949 technical specification for parts related to the automotive industry supply chain. This is the highest standard possible (Tier 1 certificate), combining the collective ideas of 12 international certification bodies, and aimed at instilling defect prevention and the reduction of variation and waste in the whole supply chain.

If you’d like to work with an electronics supplier offering quality and sustainability excellence, please do not hesitate to get in touch to discuss any of your current or new projects with us.