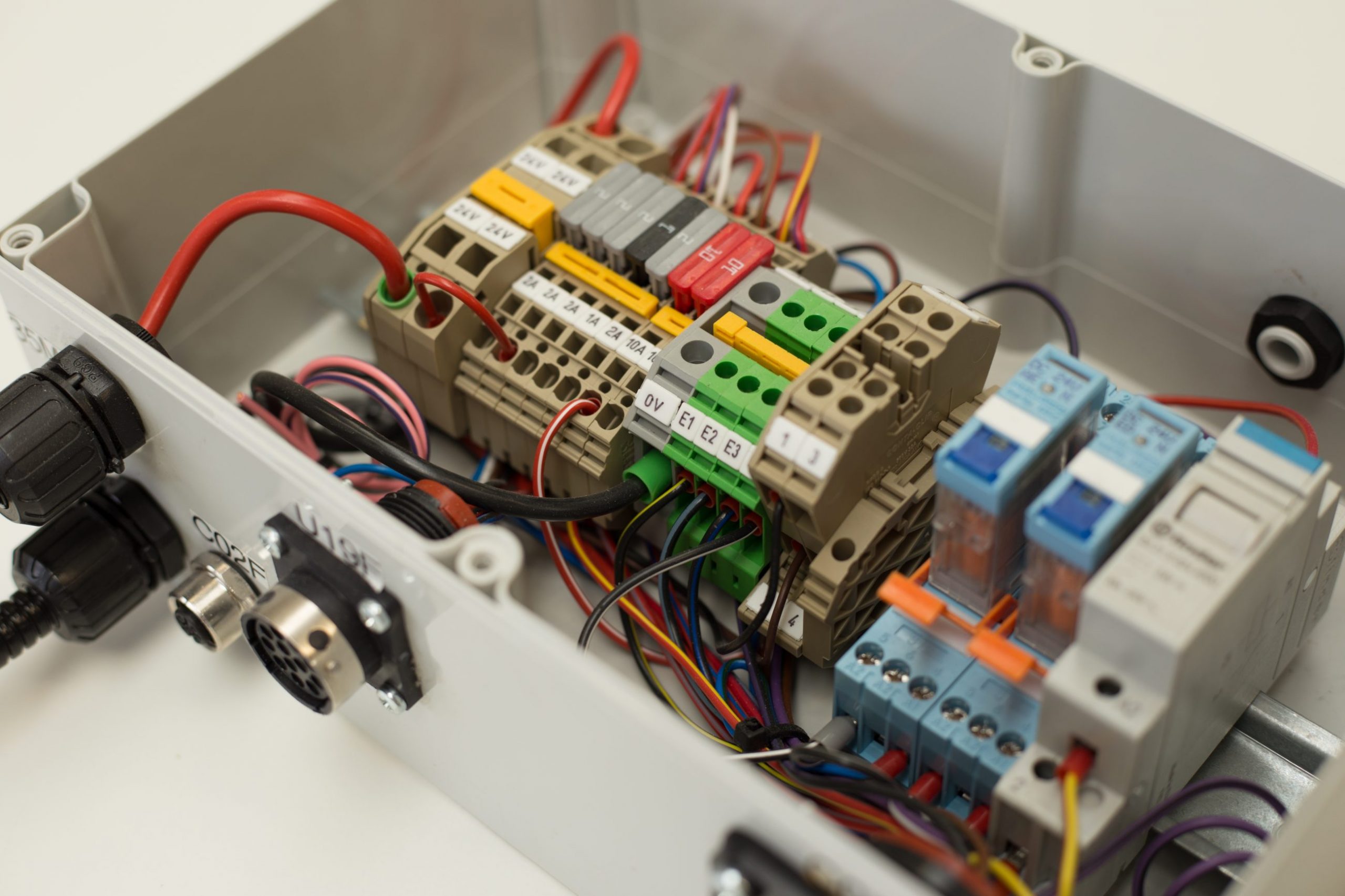

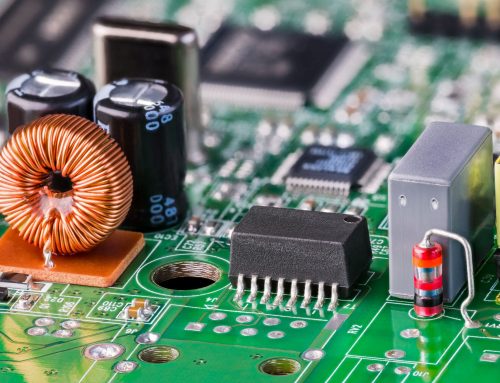

Sometimes referred to as ‘system integration’, a box build is the process of assembling a single printed circuit board (PCB) or various PCBs, along with all the connected wiring and cables, into an enclosure to create a complete ‘boxed product’. This enclosure could be made of various materials including steel, aluminium, brass, wood, plastic and acrylic.

Many different sectors rely on PCB box build assembly services; for example, the computer industry, medical, aerospace, defence, telecommunications and industrials markets. These fully assembled products are used within a number of applications such as computer servers and complex medical equipment. However, this full assembly service is also present in something the majority of us see and use every single day: our smartphones.

One step at a time

From a PCB in a small casing to a large cabinet full of wires, a box build can take many different forms and will vary greatly depending on what the project requirement is. As such, the process involved is specific to each project and can include differing degrees of complexity at each step. For example, one step could simply be placing a PCB assembly within an enclosure while a later stage may consist of the complex task of connecting it to a user interface display.

The most common processes involved in box build assembly include installing sub-assemblies and other components, routing cabling or wire harnesses and manufacturing enclosures. However, at EC Electronics, we offer the complete box building assembly service — seeing projects through from the initial design stage to testing, logistics planning and finally the end-user delivery.

By carefully studying your CAD design, our experts produce detailed drawings so you can see the exact layout of the box and ensure the delivered solution perfectly fits your brief. We will also give you a full specification of every component, including everything from the type of wiring we recommend right through to the size of the box and where the holes will be for the wires.

Once the product has been assembled and packaged to the customer’s point of sale specification, we also carry out functionality, earth bond and flash testing to ensure reliability and consistency.

Utilising a box build assembly service means you will experience a more streamlined process and see a much smoother path to market. This is because the entire process is managed in one place. As a result, box builds can prove extremely cost-effective while maintaining high-quality control of the final product.

Combining quality and value

For over 35 years, our box build engineers have been combining core electronic manufacturing skills — PCB assembly, cable and mechanical assembly — to produce boxed products for clients ready to deliver to their customers.

At EC Electronics, we source all the necessary components from our trusted suppliers, who we have worked with for many years. So, we know we can rely on them for quality and reliability, even when working to tight lead times and specific budgets.

We then manufacture all the electronics for the inside of the box at our factory in Romania before sending the components to our specialist electronics box build facility in Theale, Reading. Here, the product is assembled, tested — going through a vigorous UK-standard quality check — before being shipped to the customer’s facility in the quantities they require, on the day they need it.

From these two locations, we provide a single-source, dedicated assembly service which offers customers the best of both worlds: a final UK-manufactured product which meets stringent quality standards alongside excellent value for money and fast delivery times.

We’d love to discuss your next electronics box build project! Get in touch with our friendly team today on +44 (0)118 9325 120 or email sales@ecelectronics.com to chat through your requirements.