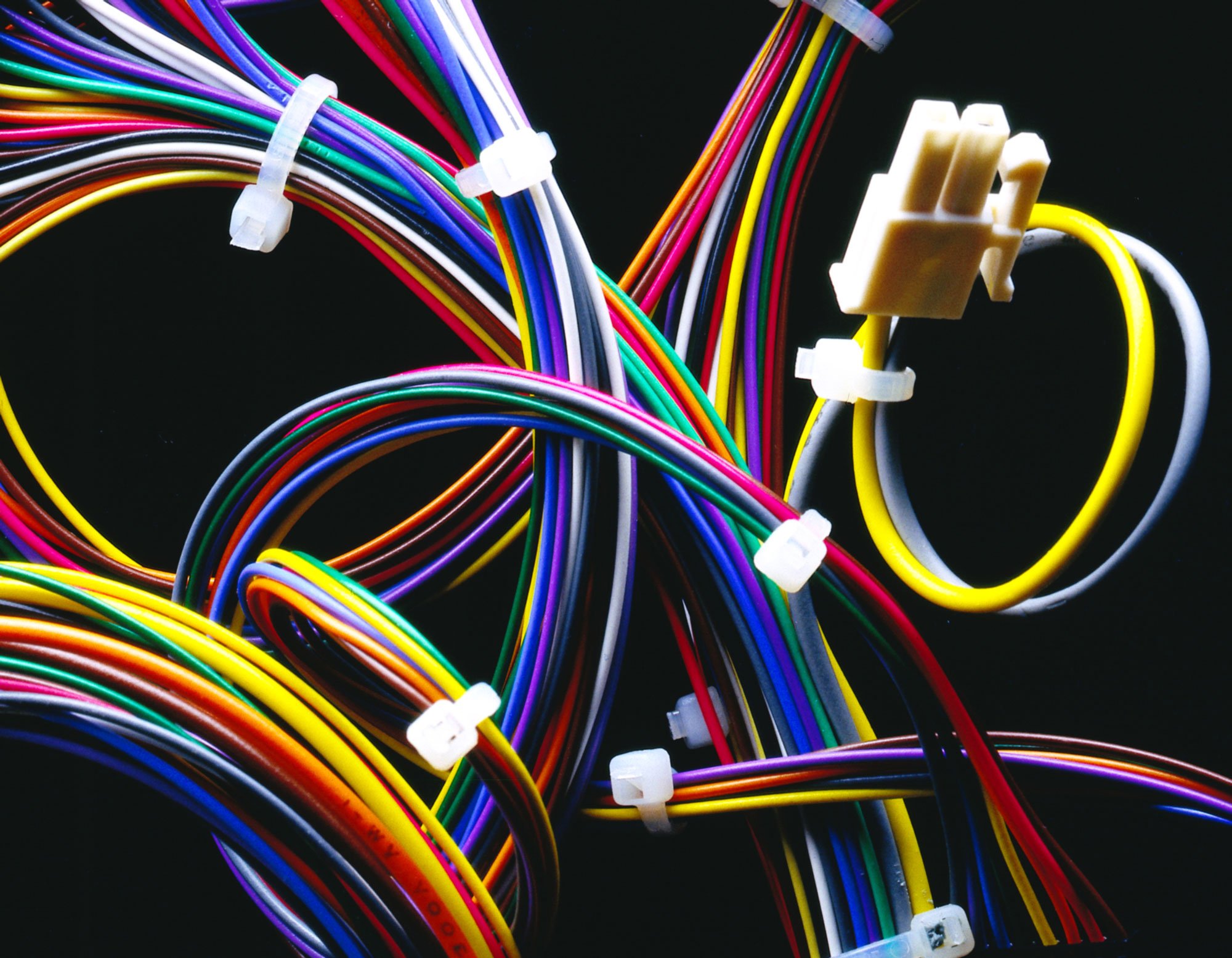

Cable Assembly

Thanks to our deep industry knowledge and vast experience, we can support customers in producing a range of complex and specific cable assembly applications.

Custom cable assemblies created specifically for the application are a valuable solution for OEMs across a range of different sectors such as Industrial, Medical, Automotive, Marine and Security.

We provide a complete cable assembly service — from design, drawing and prototyping through to full production volume.

With 40 years’ experience in electronics contract manufacturing, we have considerable knowledge across a wide range of connectors, cables and terminating equipment from all the major suppliers — such as TE Connectivity, Molex, Amphenol, JST, Alpha Wire, LAPP and Brady.

From our dedicated cable assembly facilities in the UK and Romania, we can fulfil production requirements for any cable assemblies and for any volume requirements.

Whether you are looking to be more competitive in your market or respond to short-term fluctuations in demand, we can help.

Maintaining standards

State-of-the-art preparation equipment and highly experienced staff are at the heart of our cable assembly operations. We are continuously working to industry best practices, including IPC/WHMA-A-620 Class 3 Standard, and seeking to push technology forward to improve upon our stringent quality benchmarks.

Our fully automatic Komax 255 and wire processing machines incorporate digital crimp height and crimp force analysis at every termination, ensuring high-quality assemblies every time. These advanced machines are supported by a wide range of modern semi-automatic wire preparation, crimping and marking equipment — which is used for lower volume, more bespoke cable assemblies.

To discuss your business’ needs, please get in touch with our friendly customer service team, who will be happy to talk through your requirements.

Why EC Electronics?

We’re experts in cable assembly. With five dedicated factories in Basingstoke, Hampshire, Abertillery, Wales, Amsterdam, Netherlands as well as Petroșani and Aninoasa in Romania, the unique combination of our friendly customer service team, state of the art machinery and experienced electronics manufacturers means that we can deliver your project to an exceptional standard.

From simple projects of high volume to complex projects of lower volume, we manufacture to your needs. What’s more, we’re with you every step of the way so that you have an end product which meets your exact requirements.