Low-Pressure Overmoulding

Low-Pressure Overmoulding

Low-pressure overmoulding is an innovative encapsulation process positioned between traditional potting and injection moulding technologies. As a leading electronics manufacturing services provider, we offer a quality overmoulding solution for even the most complex projects.

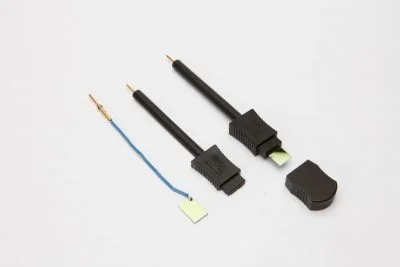

With our quality low-pressure overmoulding service you can protect your PCB and cable assemblies with an unbreakable, shock-proof solution.

What is it?

Low-pressure overmoulding is an injection process whereby a PCB assembly, for example, is placed in a specially manufactured aluminium mould tool and completely surrounded (overmoulded) with a liquid compound that effectively forms the protection for the device. LPO is a complementary technology, it does not replace all potting applications and typically does not compete with traditional injection moulding.

This process greatly simplifies the production of final packaging and offers a technically efficient and cost-effective method.

How does it work?

The moulding compounds used are called 'hot-melts' and are typically polyamide materials that are heated to 210C, forming a low viscosity material that can be injected at typically 50 – 200 psi into the mould cavity to encapsulate the electronics.

The injected material starts cooling as soon as it comes into contact with the mould cavity, thereby producing a short curing time cycle. The excellent adhesive properties form a watertight seal (IP 67 rated) around the PCB without any chemical reaction, ensuring that no toxic fumes are produced. It is the low injection pressure that is paramount in preventing damage to the electronics and unlike traditional potting applications, there is no need for a separate housing.

Tooling Costs

Typically, tooling costs starting around £2,500.

Why EC Electronics?

The use of specialist raw materials and mould equipment form the key elements in the low pressure overmoulding process. With the latest technology and 40 years of experience, we guarantee excellence and quality for your project.

We work with some of the largest companies on some of the most interesting electronics projects. Our electronics manufacturing experts will not use their vast array of knowledge to provide an exceptional service, but we will also work with you to create a quality product designed for manufacturability.