With technology changing on a daily basis and demand for new products at unprecedented levels how are the electronic component manufacturers coping. Are there enough parts to go around?

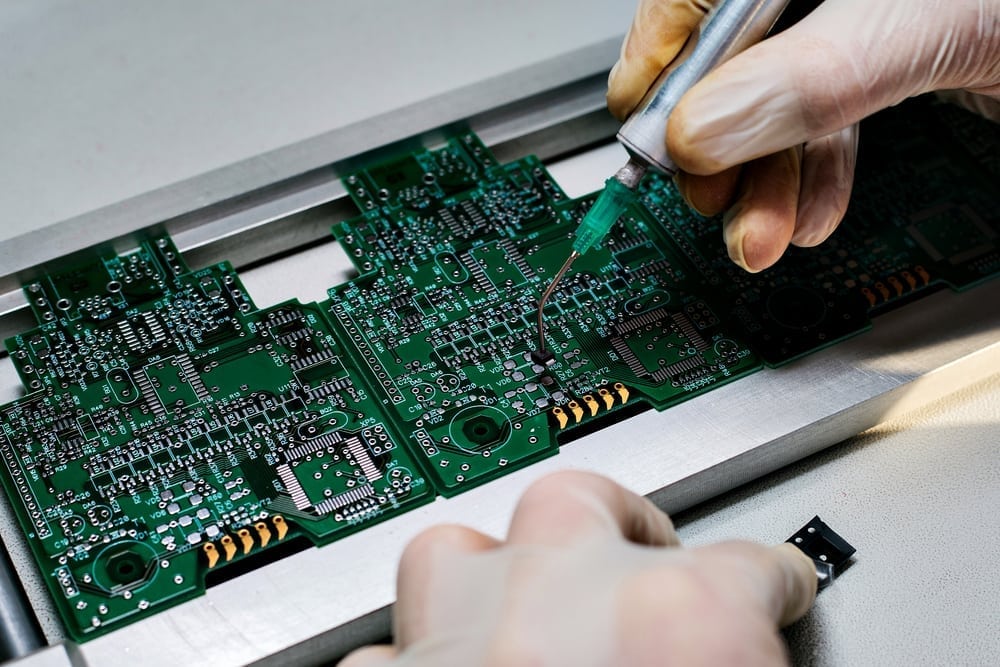

As experienced manufacturers of state of the art products such as wearable sports tech, computer tablets and advanced, ground-breaking virtual reality equipment, we are used to providing quality products using quality parts. Now, with the high demand for technologies such as SMD MLCCs, SMD resistors and Semiconductors manufacturers like Panasonic Vishay, AVX and TDK to name a few are struggling to cope with demand. In fact, they are cancelling some distributors backlogs without advising them. Should your company be concerned?

What is the impact on manufacturing?

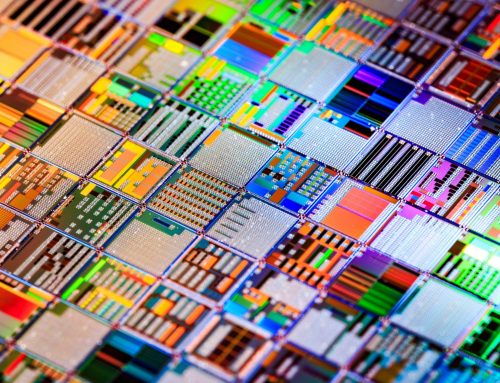

Often, we do not realise just how many electronic components are in the products we buy and how the demand for them affects the market; for example with Smart phone technology alone, the iPhone component usage has doubled since the 6S was released in September 2015. Although the Cloud continues to be a confusing entity for most, its popularity has not been affected by this. Cloud Computing is projected to increase from $67bn (in 2015) to $162bn, which means a massive increase in server production, distribution and training to clients across the world.

Increased demand on everyday products such as Smart TVs, Amazon Echo and even solar panels, puts pressure on every step of the manufacturing process and ultimately affects the consumer, resulting in a higher purchase cost at the final stage. The competitive nature of this industry, along with the demand for more complex products is putting the pressure on to create original and ground-breaking technology from companies all the way to the manufacturing source. Extended lead times, allocation and even raw material storage all has a knock-on effect on the many products we supply.

This shortage also has an impact on component manufacturing within the automotive industry. The evolution of electric cars and the demand for gadgets such as parking sensors and automatic windscreen wipers means that additional components are becoming a standard addition to vehicles. For example Electric vehicles use 4 x the amount of SM Capacitors than petrol or diesel.

What can we do about the electronics component shortage?

As manufacturers we build relationships with our suppliers in order to allow a better communicative pathway between all parties. Ultimately, this means that we have the responsibility to give the supplier enough time to get the parts and ensure that the lead time we are quoting is fair to all parties.

At the moment, the demand for parts is mightily outweighing the ability to supply them and there isn’t much we can do about it. Our need for staying connected, to have the Internet and Radio at our fingertips wherever we are, is only going to increase and put more pressure on the electronics component shortage.

If you have an idea or would like to discuss any electronics contract manufacturing project, contact us in order to discuss how the component shortage could affect your business. We aim to keep everyone updated on the realistic time scale for any project and constantly monitor trends happening within the electronics industry in order to stay one step ahead of the game.