Short timescales and high production values do not always go hand in hand. Many electronics manufacturing projects are months in the planning to ensure that products are delivered on time and to the highest quality standards. But if you have an ad hoc project that needs to be delivered fast, you don’t have to compromise on quality. With the right support you can get the best of both worlds.

Below we share the importance of having the resources to manage ad hoc projects effectively, and how to ensure deadlines and quality standards are met.

The Importance of Managing Electronics on Demand

Many companies are trying to shift from a build-to-forecast to a build-to-order model. Instead of scheduling the timing of a build, they require their supply chain to be able to manufacture components on demand. There are many benefits to this model. It increases agility, reduces overheads and the cost of holding inventory. The build-to-order model also increases the ability to customise products to meet the needs of specific customers.

The disadvantage of this approach is the time it takes to get the product to the customer. Customer expectations on timescales are high, sometimes unrealistic, which means it’s imperative that companies have the right infrastructure in place to meet demand for build-to-order and ad hoc projects.

The first step is to ensure you have the right suppliers on board, well in advance of any ad hoc projects being needed. With high demand for electronic components, it’s really important to partner with suppliers who are able to deliver. The following points should be considered:

Expertise – do they have the right expertise to deliver your ad hoc projects?

Capacity – can they cope with the unpredictability of ad hoc or build-to-order projects?

Supply chain – are they able to get hold of components quickly to meet your deadlines?

Cost – have you got an idea how much build-to-order or ad hoc projects cost compared to build-to-forecast?

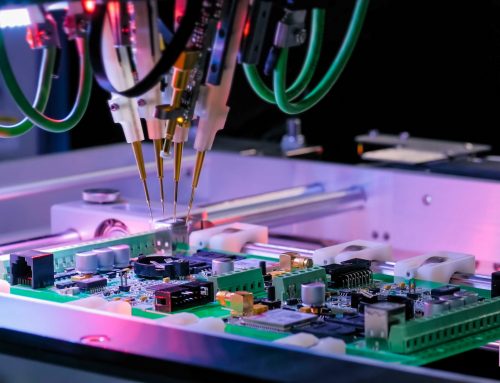

Quality – what quality assurance procedures are in place to ensure that high quality products are delivered, regardless of timescales?

It’s our belief that building strategic partnerships with suppliers like electronics manufacturing service providers is the best approach. They can help you prepare and plan for ad hoc projects. Good suppliers will want to understand your business, expectations and your end users, and develop processes to help accommodate ad hoc demand.

They may also be able to offer additional value, working with their customers to find solutions that can help speed up delivery time and reduce the cost of ad hoc / on demand products. For example, electronics manufacturing service providers with design and logistics experience may be able to recommend an alternative approach that can enable their customers to get products to market in a more efficient way.

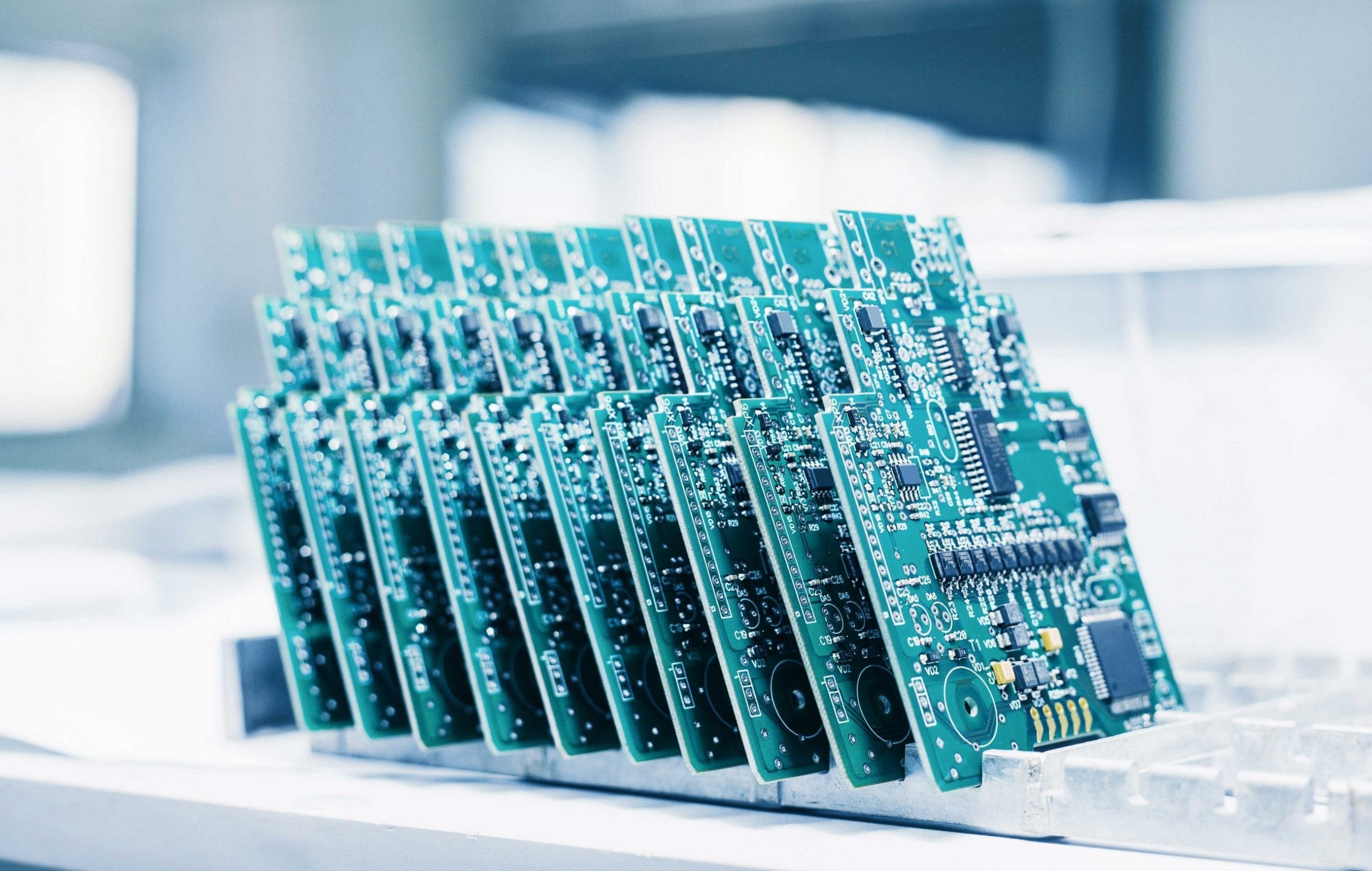

Here at EC Electronics, that’s exactly what we do. Our strategic partnerships with clients allow us to have contingency plans in place if they have unexpected demand for a product, need prototyping services, or have an ad hoc project that requires a quick turnaround.

We know that this is really important to our customers because you’ve told us so! In our customer satisfaction survey, many rank our ability to deliver projects on demand as a key reason for using our services. Combined with high expectations for customer service, and the ability to deliver a wide range of services including PCB assembly, cable assembly, box build and electronic design, this makes EC Electronics their preferred partner.

If your business has ad hoc electronics projects, or needs a build-to-order approach, we recommend that you on board trusted suppliers first. Get the right people and services in place, ensure they understand the quality standards required, and have the expertise and capacity to deliver to your timescales.

To discuss your requirements with a member of our team, please get in touch.