Every great electronic product starts with an idea. If young Robert Lucky had been too shy to share his idea for an adaptive equalizer in 1961, we would not have modems. If Lucky hadn’t gone on to brief a manufacturer with his design, we wouldn’t have personal computers. A great electronics idea can change the world.

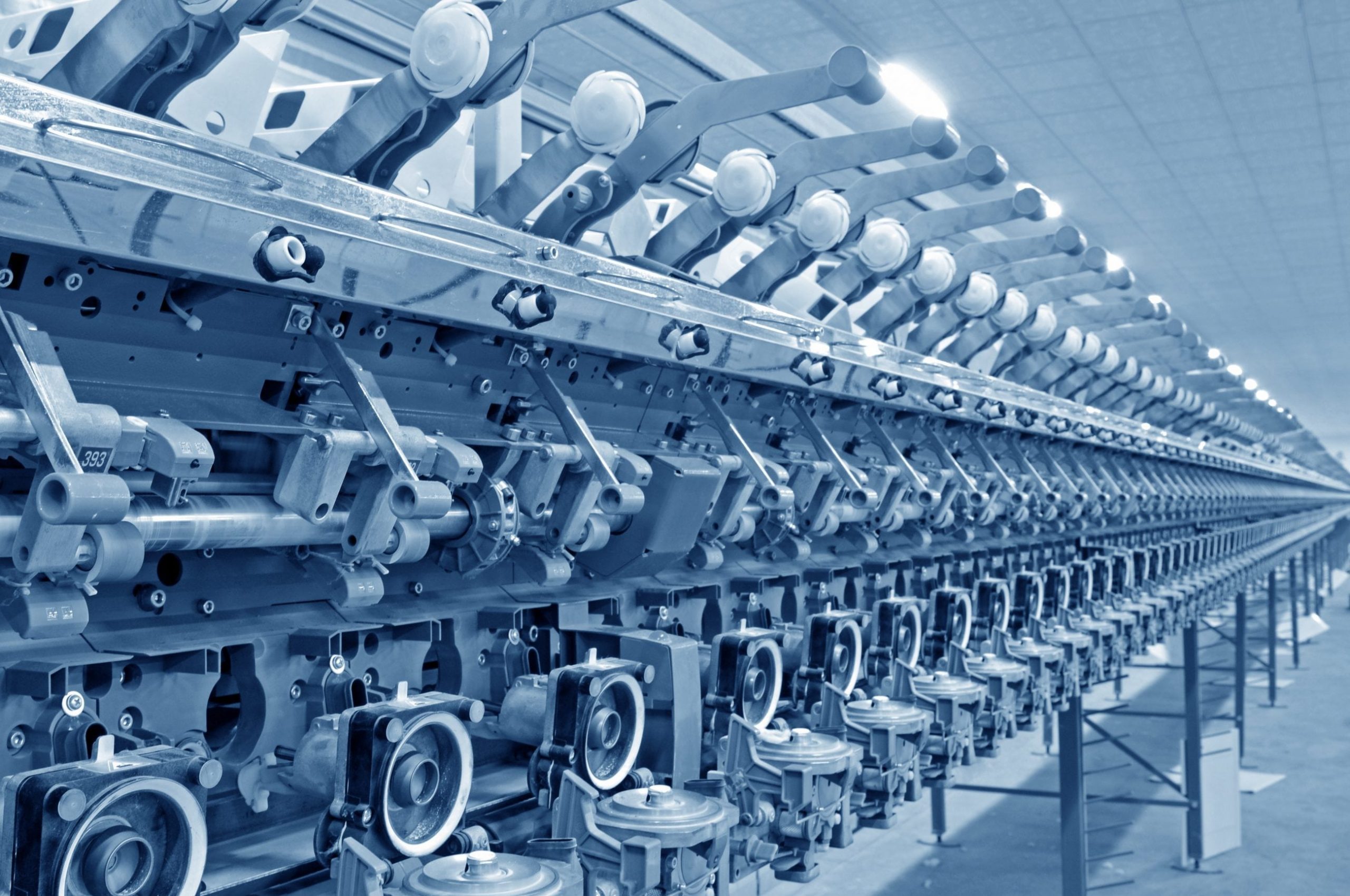

Bringing your product to life

When you’re thinking about approaching an Contract electronics manufacturer (CEM) like us for advice, consider the Design for Manufacturability (DFM) process. This could be understood as asking an expert the question; ‘how feasible is it to make my product?’ Consider DFM is a constantly evolving field of expertise, as manufacturing companies innovate and automate more stages of the process.

New product introduction phase

That being said, you need to assess how ‘ahead of the game’ the CEM/EMS partner is, what advice they can give you, and if they can bring your product to life without serious amounts of hassle. Starting with the new product introduction (NPI) stage, we rely on 30 years’ experience in the electronics manufacturing services industry to help you design your product. Our team builds a business case for you based on sound DFM protocols. Sourcing our extensive network of cutting-edge suppliers, we make your prototype and finally bring your project to life. What are you waiting for?

Five things we’ll definitely discuss with you when designing for manufacturability include:

1. Allow potential problems to be fixed in the design phase

At a first meeting, probable production problems are addressed by discussing the processes available for making a product. The order in which it is built, the automations available, the ways it could be made, and what makes it more expensive, or less expensive, as you go. Scalability and where you’ll run into further costs are important to flesh out too.

2. Choose raw materials to suit

Creating a prototype involves important decisions about materials in order to have a fully-functioning, high quality product. For example, the type of raw material, the form of the raw material, dimensional tolerances and secondary processing aspects such as finishing, all effect the end quality of the product.

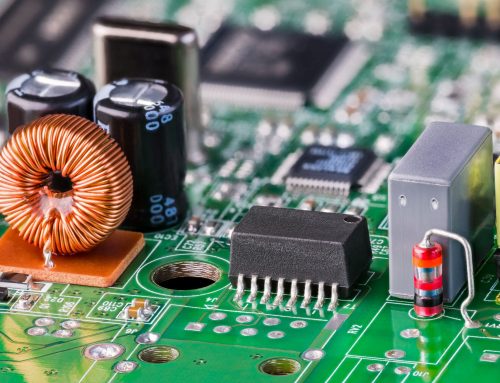

3. Adhere to set guidelines for DFM

Using our manufacturing knowledge, it’s important to adhere to various mechanical tolerances, rules and common checks related to DFM. For PCB product realisation (one of our specialist areas), the new product introduction (NPI) stage can determine if a process may be done automatically by machines e.g. surface mount technology (SMT) component placement and soldering, rather than by hand.

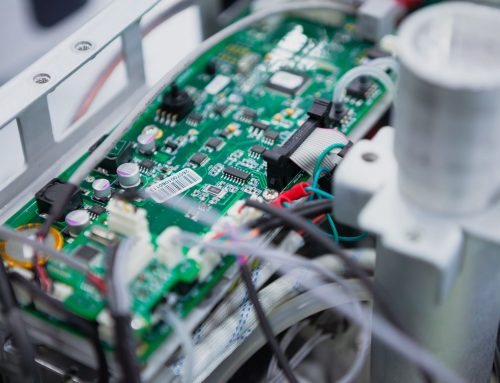

4. Adopt a new product introduction (NPI) stage

The physical layout of integrated circuit designs includes a DFM methodology to make them more manufacturable. What seems like a good idea on paper, will be improved at the NPI stage for things such as functional yield, parametric yield, or their reliability. Basically, how long it will last. Remember, for your customers, durability is important down the line and can become your unique selling proposition.

5. Go with a Product Realisation service straight to market

The final stage as you turn your thoughts into action is manufacturing and distributing your product to market. Helping entrepreneurs and established businesses to design an idea, manufacture it, create a prototype, test, and distribute it worldwide, is the most effective way to take a new product introduction (NPI) to market.

Taking your idea, your vision for electronics manufacturing design into prototype stage and beyond is best achieved using our Product Realisation service. If you’d like to discuss how we can bring your ideas into a reality you can understand, and take advantage of all our onsite expertise, please get in touch today.